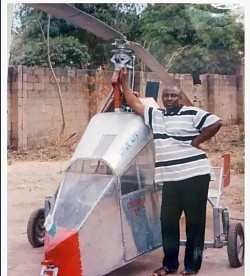

AMAZING (STOR) GYROPAPNE

Built this Amazing Short Take Off Roll(STOR) GYROPAPNE

This remarkable Gyroplane represents a breakthrough in light aviation engineering. Its unique configuration ensures superior safety and aerodynamic efficiency. Unlike conventional fixed-wing aircraft or helicopters, the Gyroplane’s rotor blades are not mechanically coupled to the engine. This design feature enables autorotation, allowing the aircraft to continue controlled flight and descend safely even in the event of an in-flight engine failure — effectively transforming it into a glider.

The Gyroplane requires a remarkably short take-off run of approximately 50 meters, thanks to its efficient rotor dynamics and lightweight airframe. Once airborne, it can achieve stable flight at altitudes reaching 18,000 feet above sea level, maintaining excellent maneuverability and fuel economy.

This aircraft combines simplicity of design, operational safety, and ease of construction — making it an ideal project for experimental builders, aviation researchers, and flight innovators.

At Glyms Industries Ltd, we continue to push the boundaries of research and development in advanced aeronautical systems. Our mission is to engineer practical, energy-efficient, and safety-driven solutions that redefine the future of personal and experimental aviation.

MAINTENANCE ON GYROPAPNE ROTOR HUB AND PRE-ROTATOR

BAMIJI WORKING ON ROTOR HUB OF GYROPLANE

HOW THE GYROPLANE ROTOR HUB AND PRE-ROTATOR WORK

The rotor hub is the central unit that holds the gyroplane’s rotor blades and allows them to rotate freely in autorotation. It uses a teeter (see-saw) hinge to let one blade rise while the other falls, automatically balancing lift during forward flight. The hub sits on a gimbal head, which the pilot tilts with the control stick to direct the aircraft. The blades have a fixed pitch, and flapping stops prevent excessive movement during low-RPM operation.

The pre-rotator is a ground-only system used to spin the rotor before takeoff. It typically uses a mechanical, hydraulic, or electric drive connected to the engine to bring the rotor up to 100–200 RPM. Once disengaged, incoming airflow takes over, driving the rotor into full autorotation for flight.